The addition of copper in high quantities gives it excellent corrosion

resistance. It is added 90 percent in the alloy. Therefore, fittings have

excellent resistance to corrosion which is often seen in salt-water and

marine environments.

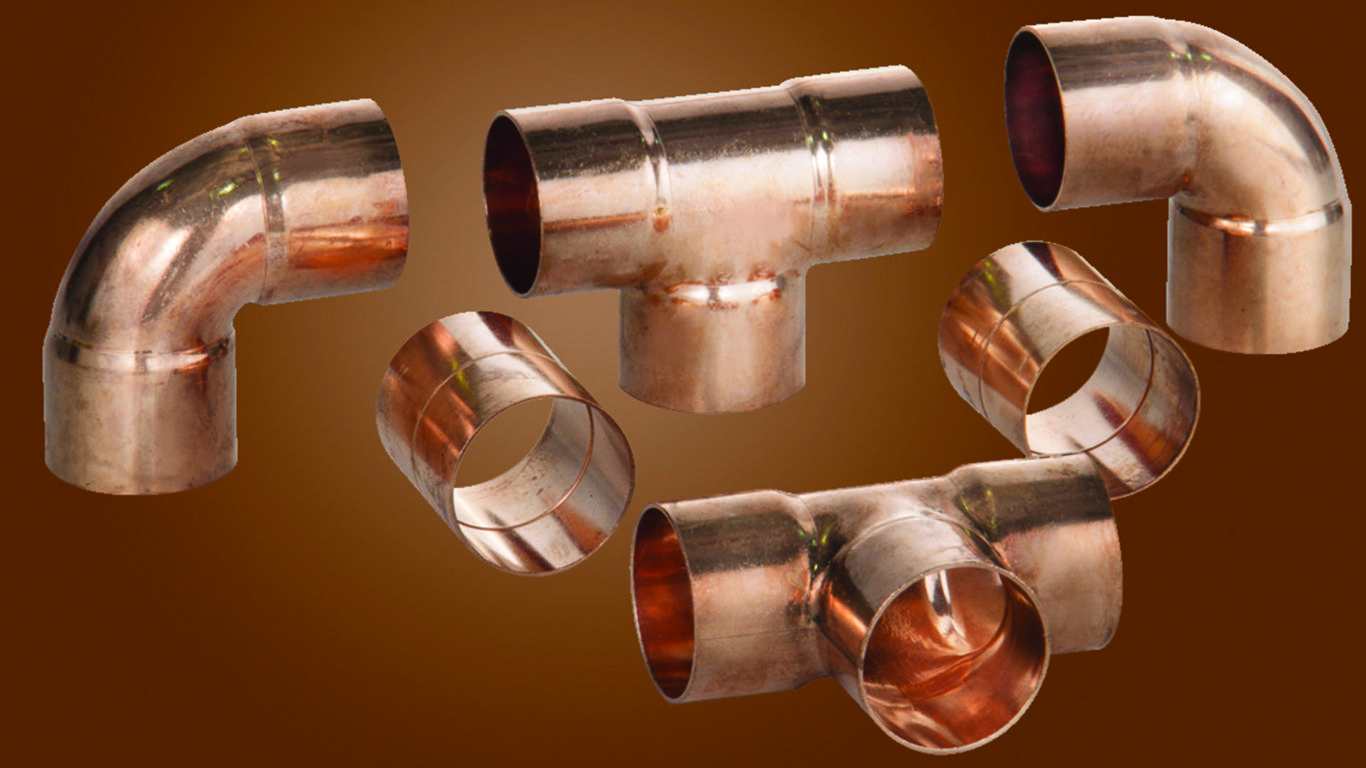

We did not serve one type of fitting to the customers; different types are

also served to the clients. Customers can ask for short-radius elbows,

reducing elbows, crosses, concentric reducers, long-radius elbows, equal

tee, seamless and welded elbows, eccentric reducers, reducing elbow, unequal

tee, and more. These are made in ANSI/ASME/ASTM standards and various

schedules. They are offered in varied specifications and sizes as well.

All the fittings have been manufactured using quality standards. These

standards are of international importance. Therefore, we serve them to

global clients as well. These are buttweld, socket-weld, threaded, flanged,

spigot, and buttress.

The fittings are procured and supplied after testing. The testing is done in

an in-house testing unit of the factory. The testing is important, and hence

we perform the resistant tests, toughness tests, hardness, tensile strength,

micro, and macro, flaring, flattening, PMI, and IGC tests.

The tests are done under the supervision of experts. Also, we do packaging

using durable and sturdy materials.

Cu-Ni 90/10 Butt weld Tee, Cupro Nickel 90/10 90

deg. Elbow, ANSI B16.9 CuNi 90/10 Pipe Fittings, ANSI B16.9 Cu-ni 90/10

Welded Fittings, CuNi 90/10 ASTM B366 90 Degree Pipe Fittings, 90-10

Copper Nickel Pipe And Fittings, Copper Nickel Pipe Fittings

Manufacturers, Cu-Ni 90/10 Pipe Equal Cross, CuNi 90/10 Reducer

Exporter, Copper Nickel 90/10 Eccentric Reducer, Cu-Ni 90/10 End Pipe

Cap, Cupro Nickel 90/10 Pipe Bend, CuNi 90/10 Pipe Fittings Manufacturer

in Mumbai.

Cu-Ni 90/10 is a copper-nickel alloy that contains 90%

copper and 10% nickel. It offers excellent corrosion

resistance in seawater and other marine environments,

making it a popular choice for piping systems in

shipbuilding, offshore & other industries.

Industries that commonly use Cu-Ni 90/10 Pipe Fittings

include shipbuilding, offshore oil and gas,

desalination, power generation & chemical processing.

They are used in applications where resistance to

corrosion in marine environments is crucial

The maximum operating temperature for Cu-Ni 90/10 Pipe

Fittings depends on the pressure and the environment. In

general, they can withstand temperatures up to 150°C

(302°F) in seawater and up to 250°C (482°F) in

non-oxidizing environments.